Tesla’s Cybertruck, the legendary stainless steel monster considered the future of electric pickup trucks, is facing another obstacle—and this time it’s literally breaking. A recall of over 46,000 vehicles—almost every Cybertruck delivered to date—has sparked renewed criticism of the vehicle’s quality control. But it’s not just the extent of the recall that’s causing a stir. It’s the nature of the repair.

Glue, patches, and a pair of gloves. That’s the solution. And for some early adopters who have shelled out over $100,000, things aren’t going smoothly.

In mid-March 2025, Tesla recalled 46,096 Cybertrucks. The defect affected a steel panel—the so-called “cap rail”—that runs along the top edge of the side windows. Reportedly, the panel could detach while driving, posing a safety risk not only to the driver but also to those around them.

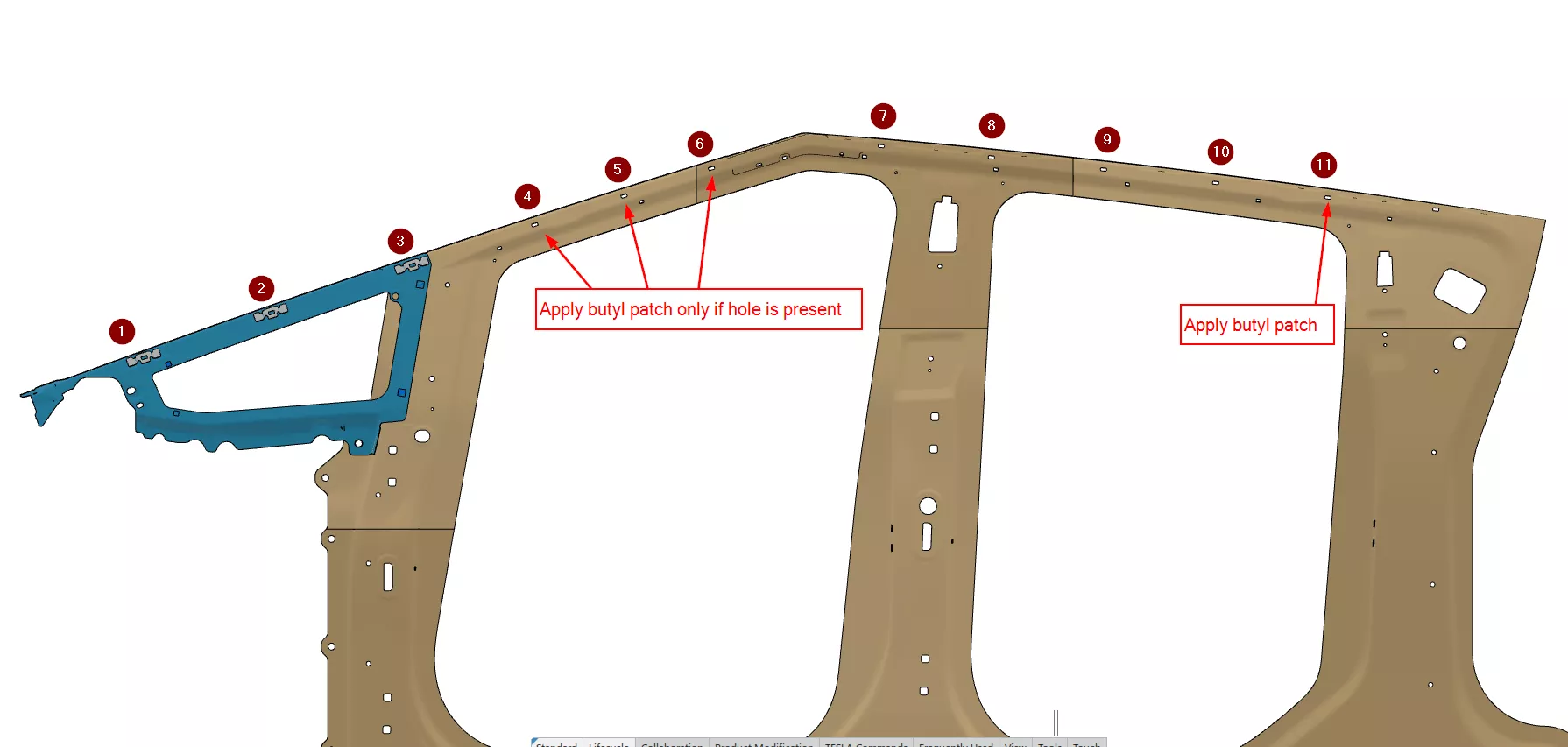

The recall, which was announced via Tesla’s service briefing and is now publicly known, involves applying butyl adhesive patches to the roof rails and securing the E-Ds with two new patches attached to existing bolts. Depending on the vehicle, technicians may apply two or eight patches, depending on how secure the patch appears after inspection.

The simplicity of the solution might be reassuring in another context. But for Cybertruck owners who expected military-grade durability and impressive elegance, it feels more like an emergency repair than a factory fix.

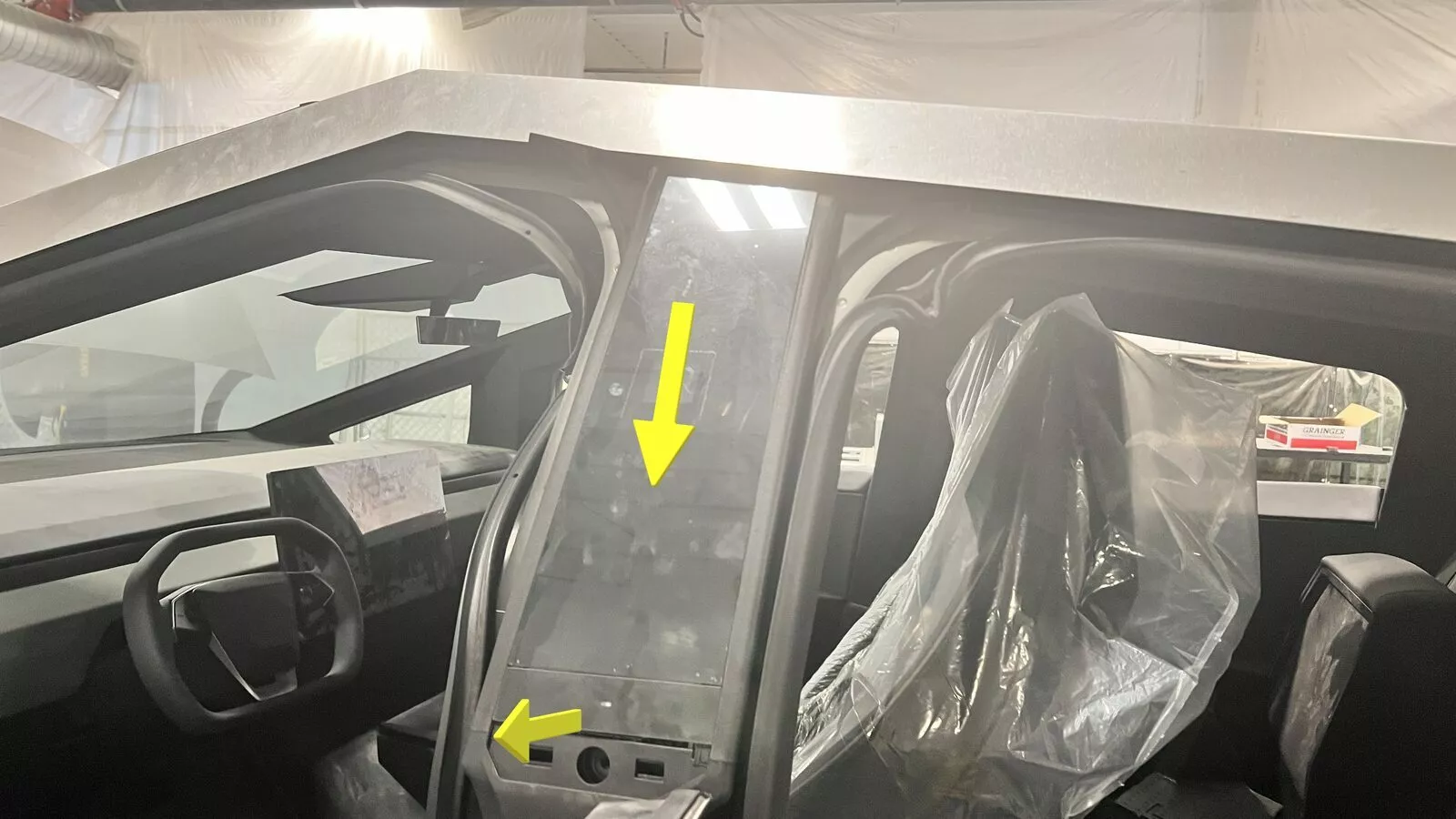

While Tesla’s repair appears straightforward on paper, its practical implementation has already drawn criticism. A Cybertruck owner, posting on the “Cybertruck OwnersClub” forum under the handle @CTDriver, described his problematic experience after the repair:

“I finally picked up my truck yesterday after the service appointment,” he wrote. “The tailgate trim doesn’t look good at all. The gap has narrowed a bit, but it still looks very uneven and misaligned. Also, there’s a circular scratch (weld mark) on the underside of the new trim. I also found a few scratches on this new trim.”

For a vehicle that can cost between $80,000 and $100,000—and in some cases even more due to resale premiums or early access bonuses—these cosmetic and quality defects are extremely serious. Worse still, the marking suggests that heat treatments—possibly welding or grinding—were used during the repair, although Tesla’s official procedure doesn’t mention this.

“Tesla should NOT have their aftermarket welding done at a shop,” the owner wrote. “They should produce a clean part from the factory with the screws/bolts already installed. This is reasonable for a large and reputable vehicle manufacturer and difficult to swallow as an early adopter.”

Tesla’s repair documentation confirms that many trucks were delivered without proper rail fasteners. The service letter describes how technicians should check the correct position and fastening of the bolts at both ends of the rail. The repair process is also explained via video.

The question is: How could these trucks even leave the factory without this critical hardware correctly installed?

The answer likely lies in Tesla’s history of product iteration—a “build fast, fix later” philosophy that has characterized, for better or worse, the company’s manufacturing approach since the Model S. But while that approach might be acceptable for a $40,000 sedan, it’s a harder sell for a six-figure truck marketed as indestructible.

The Cybertruck was meant to redefine the idea of an electric vehicle: rugged, minimalist, and futuristic. But with incongruous features, visible scratches, and makeshift repairs, including glue and other minor tweaks, some early adopters feel like paid beta testers.

Another aspect of this story concerns Cybertrucks that have been wrapped by third-party companies. Many owners have chosen to customize their trucks with vinyl wraps in various finishes—matte black, satin white, and even camouflage.

However, Tesla has stated that the films could be damaged during the recall when technicians remove and reattach the rails. Even more problematic, the company says it will not compensate customers for damage to the films, even if it occurs as part of a mandatory safety recall.

For owners who have paid thousands of dollars for their custom wraps, this presents a lose-lose situation: they either risk cosmetic damage or delay the recall and end up driving a truck with a potentially dangerous defect.

One of the most common complaints about Tesla’s customer service concerns its lack of consistency. With only a few authorized dealers and a limited number of company-owned service centers, Tesla operates a direct-to-customer model that emphasizes speed and software-based diagnostics.

But when it comes to physical hardware issues—especially in the development of structural papers—Tesla’s approach may seem underfunded. Service centers often appear overwhelmed, with long wait times and questionable quality of execution.

This could explain why some items came back with scratched paper and heat marks: the technician may not have had the right tools or training, or may have been put through a high-volume recall process.

To Tesla’s credit, there are currently only a few documented cases of post-repair dissatisfaction circulating in public forums. That’s not to say more cases won’t emerge, but at this point, it’s unclear whether this is a systemic issue or a misfire.

Still, the optics aren’t good. When the solution to a high-profile recall consists of glue, patches, and a few blinkers, expectations for workmanship rise significantly. Every faulty repair becomes a potential cause for criticism, especially from vocal and tech-savvy customers.

And while Tesla’s design team may argue that the solution is structurally sound—and it may well be—the objective quality experience is a different matter entirely.

The Cybertruck has always been a paradigm of contradictions: brutal yet high-tech, minimalist yet oversized. It’s also Tesla’s most polarizing vehicle yet, with sharply divided opinions between die-hard fans and vocal critics.

This recall—and its simple solution—underscores the challenges Tesla faces in scaling production of a highly complex, non-traditional vehicle. The stainless steel exoskeleton, for example, is more difficult to machine than conventional automotive sheet metal. This impacts not only manufacturing but also repair and maintenance.

In an attempt to redefine vehicle production, Tesla may have overlooked the realities of equipment details, part tolerances, and surface finish. And while this may be forgivable in a prototype or pre-production model, it becomes a liability once the trucks are delivered to paying customers.

The phrase “Glue, patches, and some patches” is quickly becoming a meme among Cybertruck drivers—a symbol of what happens when cutting-edge design meets expert repairs. For Tesla, it’s a reminder that innovation and execution must move quickly.

As more and more Cybertrucks hit the road, we’ll be watching closely to see if this solution holds up—and if Tesla can regain the trust of its early adopters who expected a fix and a subsequent repair.

Until then, one thing is clear: The Cybertruck may be made of stainless steel, but its casing is not scratch-resistant.