Henry Ford: The Man Who Turned Cars From Luxury Items into Popular Items.

With unremitting efforts and groundbreaking innovation, since its founding, Henry Ford has turned the dream of owning a car for millions of Americans into reality.

Henry Ford didn’t invent the automobile – Karl Benz did it many years before him. He also didn’t invent the assembly line, but he’s certainly famous for revolutionizing the industry. Worldwide, Henry Ford is known as an innovator, a “shark” of American industry. Ford may not have invented everything from scratch, but he knew how to take existing innovations and develop them into extraordinary things. He wanted to turn the idea of a luxury car into a vehicle for millions of Americans.

Henry Ford’s journey began in 1863, when he was born into a farming family in Dearborn, Michigan. From a young age, Ford showed curiosity and an innate ability to play with machines. Once, when his father gave him a pocket watch, Ford disassembled it and then successfully reassembled it. This ability quickly became famous in town as he repaired watches for friends and neighbors.

Ford’s passion for mechanics brought him to Detroit when he was 16 years old, where he began working as an apprentice mechanic. His first job was at the Flowers Brothers machine shop, where he earned $2.50 a week machining brass valves on a milling machine.

In 1882, Ford returned to the family farm but was not interested in farming. Instead, he upgraded local farmers’ steam engines and took on side jobs in factories and sawmills.

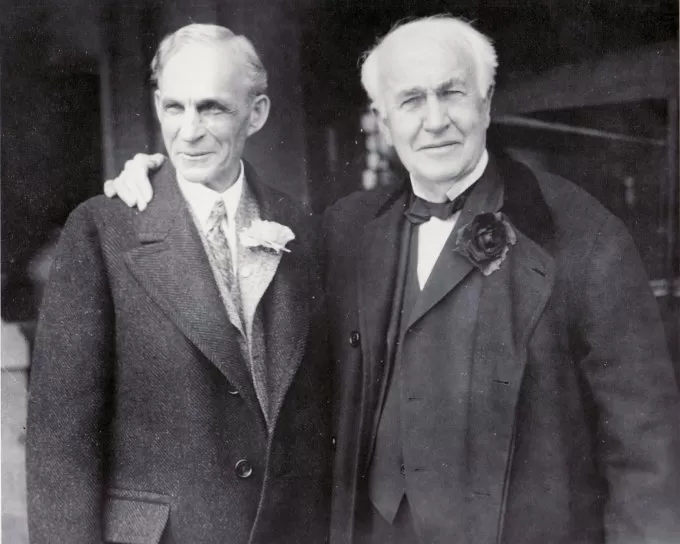

In 1888, Ford married Clara Bryant, a girl from the same hometown. Tired of running a sawmill to support their family, they returned to Detroit in 1891, where Ford worked as an engineer for inventor Thomas Edison’s Edison Electric Lighting Company. Ford didn’t know much about electricity, but he saw this as a learning opportunity.

In just two years, Ford was promoted to chief engineer. Despite the odd job, Ford spent time developing the first prototype of a gasoline car in his workshop. Thanks to the support of his friends, his efforts were rewarded with the first self-driving car, Quadricycle. The two-cylinder, 4-horsepower gasoline engine is reinforced in a lightweight metal frame with four bicycle-like wheels. The car only has two forward gears and cannot go backwards.

With the success of the Quadricycle, Ford built a second vehicle in 1898, attracting the attention of businessmen. However, his first two ventures failed because Ford focused on improving cars instead of selling them to the market.

Turning to racing cars, Ford developed several racing car models, attracting finance to prepare for a new start. In June 1903, Henry Ford and Alexander Malcomson, a wealthy businessman in Detroit, founded the Ford automobile company with a capital of 28,000 USD and 21,000 USD promised from friends, relatives and other business relationships.

Ford’s dream has come true at the Ford automobile company. He not only built luxury cars but also wanted to sell cars to ordinary Americans. As Ford once declared, “I will build cars for the masses. The price will be so low that anyone can own one.”

This dream became a reality with the company’s first car, the Model A, sold to a dentist in Chicago in July 1903. In 1904, more than 500 Model A cars were running around the streets. In 1907, Ford launched the Model N four-cylinder engine priced at $600, which was just the beginning.

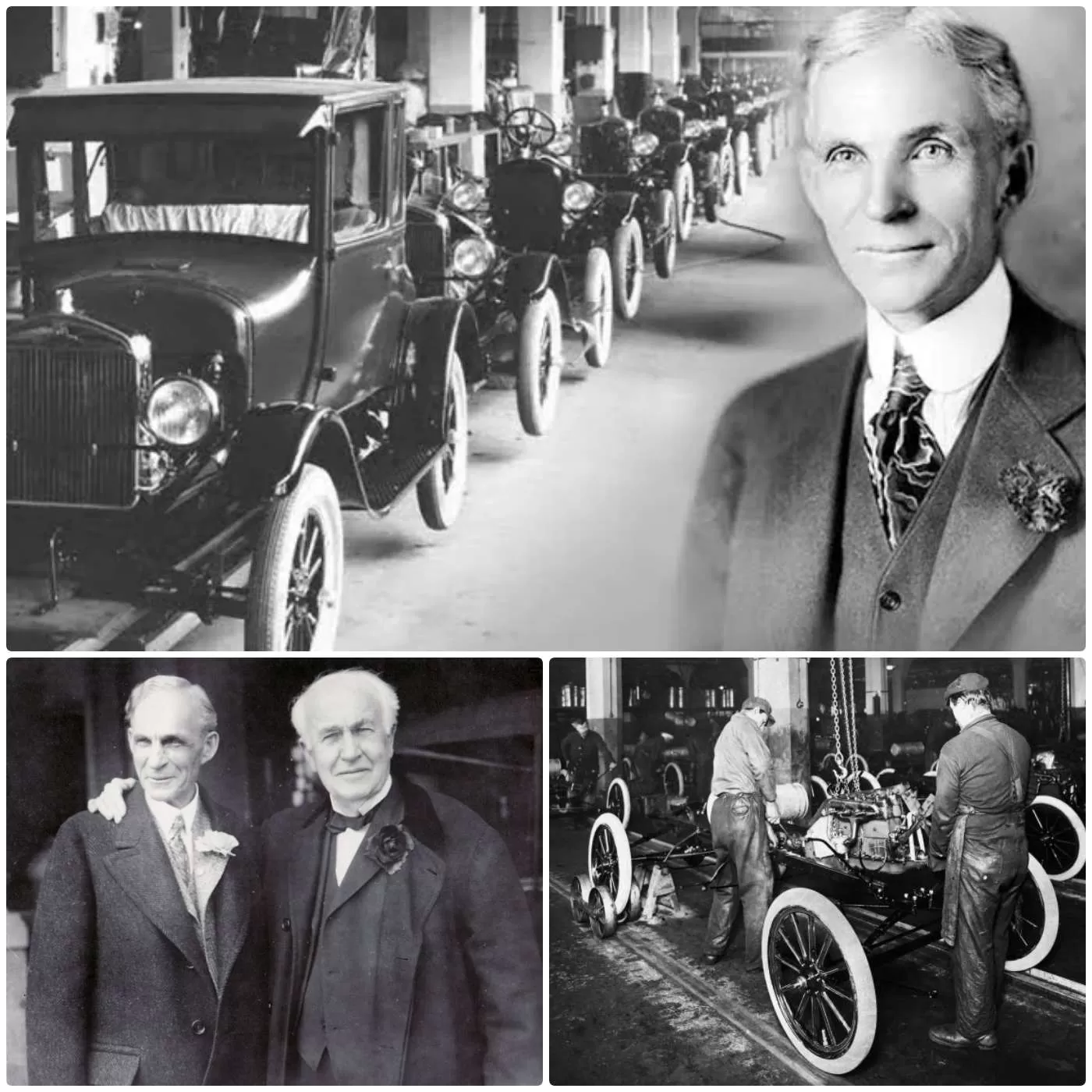

On October 1, 1908, Ford launched the Model T, an inexpensive car that was easy to drive, handle rough road conditions, and was simple to maintain. More importantly, its price is affordable for middle-class Americans.

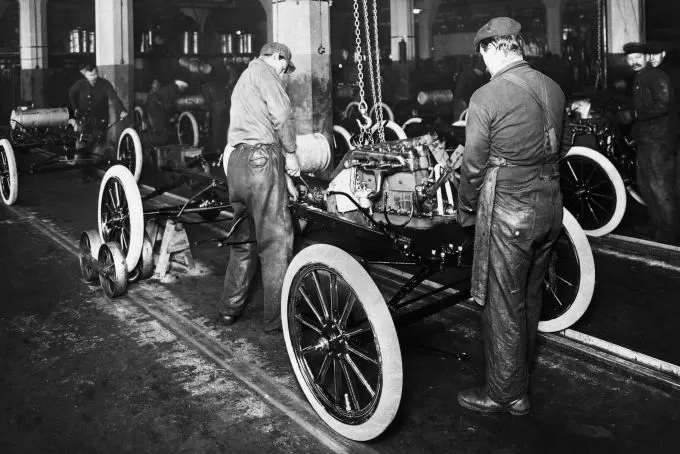

The Ford Model T quickly attracted orders and Ford could not produce it in time. To meet demand, Ford built larger factories and changed the way cars were built. He researched production techniques from other industries and gathered ideas into revolutionary production processes. Ford’s argument was that if workers performed a single task, they would build cars more efficiently. In August 1913, Ford used ropes to drag the Model T frame across the Michigan factory floor and successfully assembled the car. Production time from 12.5 hours reduced to 93 minutes.

Increased productivity helped Ford lower Model T prices, but also created problems for repetitive workers. The turnover rate is high, Ford has to hire 1,000 workers for every 100 jobs. To keep workers, he pays $5 a day, twice as much as his competitors. Salary increases not only stabilize staff but also help employees buy cars they make.

By 1922, half of all cars in America were Model T, selling for as low as $269. Henry Ford succeeded in realizing his dream.

In the late 1920s, Ford dominated the auto industry with the Model T. In 1919, Ford bought back the shares and became the sole owner. However, the success of the Model T convinced Ford that this was the only car people needed. He ignored it